Rotary fayil alamun hakori-5.18

Dukanmu mun san cewa a cikin masana'antar samfuran niƙa, akwai samfuri mai shahara sosai - fayil rotary carbide.Muna bin kididdigar da ba ta cika ba.

Mun gano cewa bisa ga kididdigar da ba ta cika ba, rayuwar sabis na carbide burr yana da tsawo, wanda ya ninka sau goma fiye da na kayan aikin ƙarfe mai sauri kuma fiye da sau 200 fiye da na alumina nika dabaran.A ƙasa akwai nau'ikan haƙora daban-daban da muke samarwa bisa ga buƙatun niƙa daban-daban.

1.Single-cut burs: Daidaitaccen yanke don aikace-aikacen gabaɗaya.

2.Double-cut burs: Sau biyu yanke don amfani da mahimmanci.Yana inganta sarrafawa kuma yana rage kwakwalwan kwamfuta.

3.Alu-cut burs: Fast Mill yanke don saurin hannun jari na cire kayan da ba na ƙarfe ba tare da robobi.

Fayil na Karfe 5.18

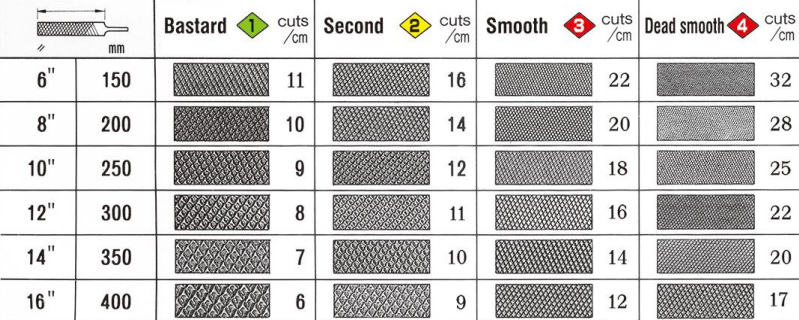

Idan kuna sha'awar yin sana'ar ku, ko kuma kuna buƙatar kayan aiki don goge abubuwa, to, fayil ɗin karfenmu zai biya muku bukatunku, gwargwadon tsarin haƙori, ana iya raba shi zuwa nau'i huɗu, wato yanke bastard, yanke na biyu, yanke santsi. , matattu santsi yanke.Yafi bisa ga daban-daban bukatun na nika, bukatar zabi daban-daban yanke iri.

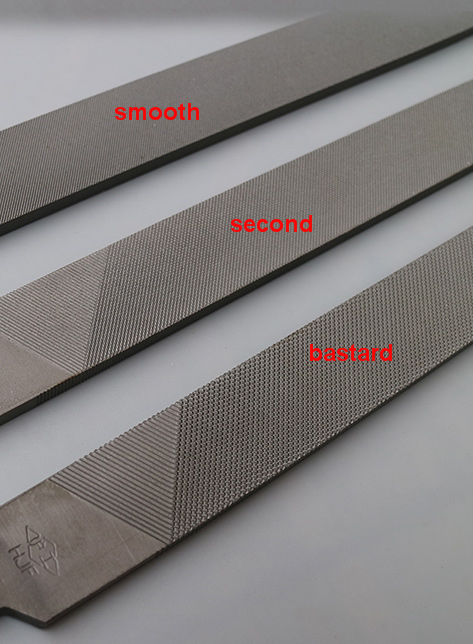

A cikin hoton muna iya ganin nau'ikan hakora guda uku da aka fi amfani da su.

1.Bastard Cuts ya dace da m workpiece da na farko siffata

2.Second Cuts ya dace da machining tare da izinin machining fiye da 0.5mm.Ana iya aiwatar da manyan injin ƙarar yankan don cire ɓangaren tare da ƙarin izinin aiki.

3.Smooth Cuts ya dace da machining tare da izinin machining na 0.5-0.1mm.Ana iya goge su a hankali don kusanci girman da ake buƙata na kayan aikin.

4.Dead Smmoth Cuts fayil shine fayil ɗin tare da ƙaramin hakora.Sakamakon yankansa kadan ne.Ana amfani da shi musamman don datsa roughness na workpiece surface.An yi amfani da shi don kammala aikin surface.

Wannan shine yadda muke rarrabe layin hakori.

Lokacin aikawa: Juni-21-2022