Cibiyar rawar jiki

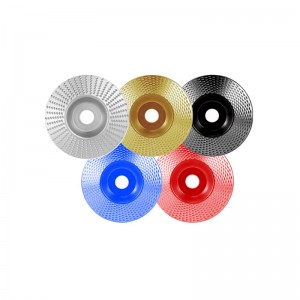

Bayanan asali

Rayuwar sabis na wasan motsa jiki na cibiyar ya dogara da dalilai da yawa, irin su nau'in kayan aiki, yanayin yanke, hanyoyin sarrafawa, da dai sauransu. da za a maye gurbinsu cikin lokaci don tabbatar da ingancin sarrafawa da inganci.Don ƙarin takamaiman bayani, ana ba da shawarar tuntuɓar ƙwararrun masana'anta ko ƙwararren masani.

Ana amfani da rawar tsakiya kamar haka:

1. Lokacin shigar da rawar tsakiya, zaɓi tsakiyar rawar jiki wanda ya dace da aikin aikin.

2. Tabbatar cewa ƙwanƙwasa ƙwanƙwasa na tsakiya ya bayyana a fili kuma mai kaifi, kuma babu lalacewa ko alamun tasiri tsakanin shaft da yanke.

3. Saka shank na rawar tsakiya a cikin ƙugiya kuma ku manne shi.

4. Alama wurin ramin da za a haƙa a kan farfajiyar aikin kuma sanya alamar tsakiyar tare da layin kwance na gubar hydroxide.

5. Fara latsa rawar jiki a ƙananan gudu yayin da a hankali sanya rawar tsakiya a kan tsakiya.

6. Lokacin da rawar tsakiya ya fara hakowa, ya kamata a kiyaye shi a tsaye kuma kada a yi aiki da shi ba tare da izini ba, don kauce wa karkatar da wurin hakowa.

7. Bayan da aka yi rami na tsakiya zuwa zurfin da ake so, dakatar da aikin motsa jiki, cire tsattsauran ra'ayi, kuma shafa shi da tsabta tare da zane mai tsabta.

8. A ƙarshe, ƙara aiwatar da ramukan da aka haƙa tare da ƙarin ƙwanƙwasa kamar yadda ake buƙata.Kula da aminci lokacin amfani da rawar tsakiya don guje wa raunin da aka kama da yatsun hannu yayin hakowa ko fadowa daga injin hakowa yayin hakowa.